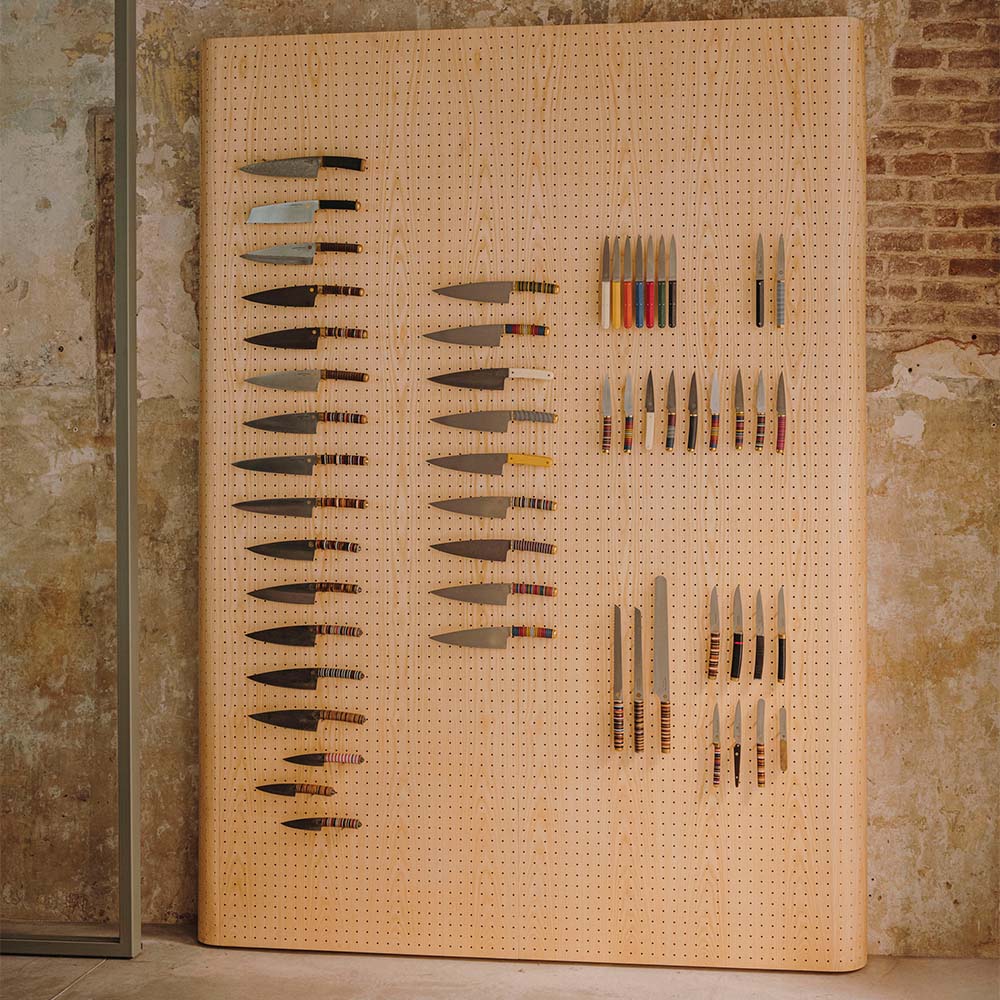

Tomer Botner – Knife maker

Hand made premium kitchen knives with unique design

In an old industrial building with huge arched windows, just a couple of blocks away from the beach in Barcelona, you’ll find Florentine Kitchen Knives. The interior is remade to perfectly fit the needs of a high-end knife production. A knife making studio where the founder Tomer Botner designs, creates and sells his hand made knives - both to professional chefs and devoted amateurs who put quality first.

Well known and unique

Florentine Kitchen Knives proves that a well made premium knife has the ability to completely change the cooking experience. Their knives are a fusion between east and west. And that is shown throughout all parts of the knives – the shape of the blades and the design elements handcrafted to the tiniest detail. The end result is a modern but timeless knife design with distinct features signed Florentine Kitchen Knives.

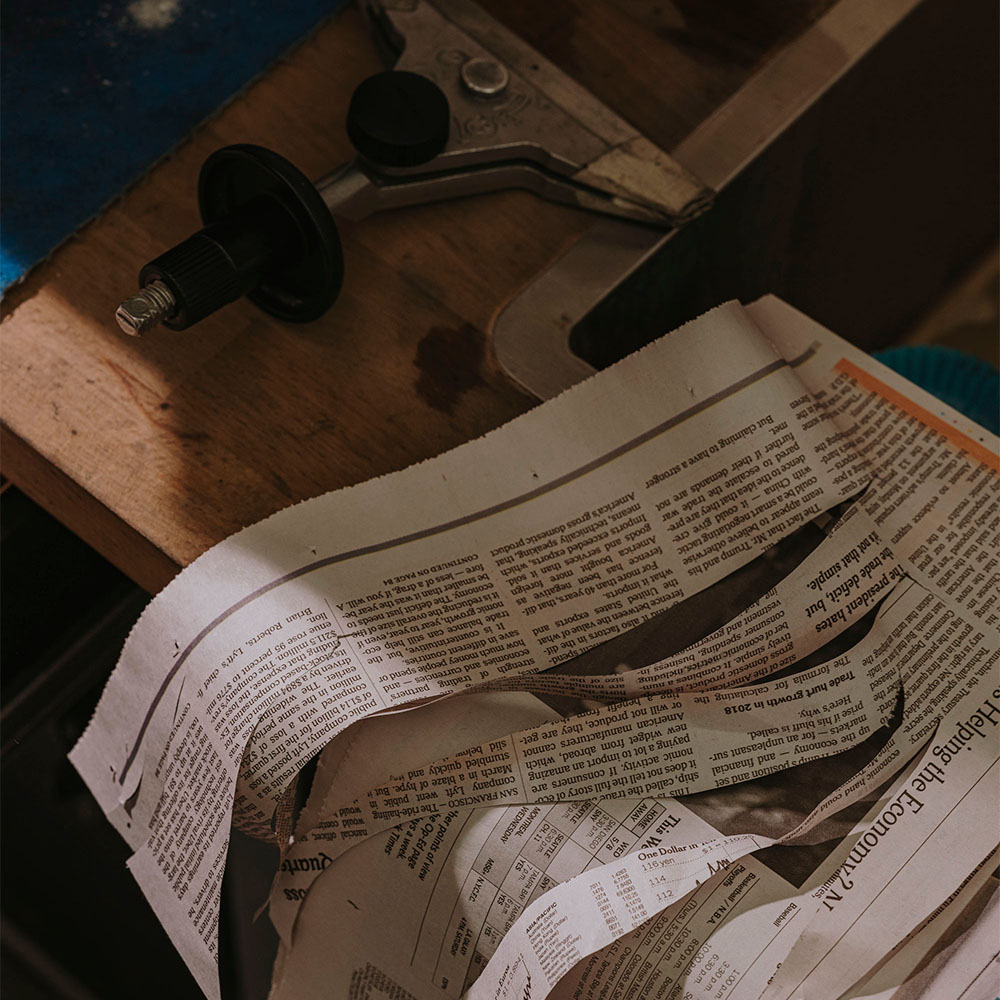

I've been using Tormek daily since 2018 and it's the best sharpening system I've ever used. Anyone can achieve great edges with it with no mistakes and no scratches. The Tormek system gives us accuracy and consistency. A quickly and easily repeated result each and every time. Our T-8 sharpening systems have sharpened each and every single Florentine line knife that left our shop and we stand behind it 100% and would recommend it to any shop owner or maker who wants to be able to have all his team sharpen or simply have a nice clean edge in minutes. Most of all I value the reliability of the machine and the adaptability to different needs while maintaining a superb result.

Tomer Botner

Florentine Kitchen Knives

Tomer's choises for his Tormek T-8 Custom

"As I sharpen about 100 knives a week in my work, I have different requirements than most people. I need things to be accurate and efficient in terms of time but without compromising the quality of the edge."

Grinding wheels

First, I pick the SG-250 Blackstone Silicon for faster removal of material. Unlike the diamond grinding wheels I like the option of trueing the stone with the TT-50 Truing Tool and having the size match and progress with my other grindstones. I prefer to work with a more aggressive stone that saves me some time but gives me the same results. I keep this stone at 220 grit constantly.

My second Grinding wheel would be the SG-250 Original Grindstone which I keep at 1000 grit constantly using the smooth side of the SP-650 Stone Grader.

To achieve that really fine polished edge I would also add the SJ-250 Japanese Waterstone, since it gives a smooth sharp mirror finish to our blades and I would highly recommend it if you want to up your game, even though the leather honing wheel does a great job.

Jigs

I use both the SVM-45 Knife Jig and the SVM-140 Long Knife Jig all the time, they are perfect for almost all kitchen knives, weather they are big or small, thin or thick, short or wide, flexible or more rigid.

Accessories

You got to have the WM-220 AngleMaster (included with the Tormek T-8 Custom), it's especially helpful when you are establishing the secondary bevel on a few different models of knives, makes everything go fast and accurately.

For accessories I'd start by adding the US-430 Extended Universal Support. The regular support works great, but for any knives that we make or get to sharpen that are over about 240-250 mm blade length, I use the extended support. Otherwise you would need to start practicing your free hand sharpening.

The SP-650 Stone Grader is great when you want to adjust the grindstone to a finer or more rougher sharpening. If you don’t get all three grinding wheels that I have, the stone grader is essential to change the surface between 220-1000 grit on your grindstone.

And finally, I would add the RB-180 Rotating Base. This thing is the best, so useful for someone like me, just turn it and hone your edge instead of lifting the machine off the table and turning it each time.

Honing Wheels

Since I have two Tormek’s in my workshop I would prefer to have them both. The LA-220 Leather Honing Wheel gives a great polished edge with the PA-70 Honing Compound but I also like the CW-220 Composite Honing Wheel and not having to use the compound which adds to our cleaning process and waste.